Climate Change in Iraq and the Kurdistan Region: Consequences of Increased Oil, Electricity, Cement, and Iron Production on Water

18-10-2023

Overview

Iraq ranks among the top 25 countries grappling with severe water shortages, as per recent data from the World Resources Institute (WRI). It consumes over 80 percent of its available water resources. Persisting with such extreme water scarcity poses serious threats to lives, employment, food and energy security. Without improved water supply and usage management, compounded by population growth, economic expansion, and climate changes, Iraq faces an escalating annual increase in the risk of water scarcity. This heightened risk may become insurmountable in the future. Moreover, when a nation experiences water pressure[1] issues, it results in a situation where despite unlocking water faucets and pipes, they remain dry. Consequently, governments are compelled to reseal them, a scenario that has become increasingly prevalent in various regions, including Iran, Britain, India, Iraq, and more.

Excluding the Kurdistan Region, Iraq presently boasts the world's fifth-largest oil production at 4.520 million barrels daily, ranking second among OPEC nations. Its output constitutes 10 percent of the global oil supply, with an annual production growth of 10.2 percent in recent years. Iraq has ambitious plans to elevate its production to 7 million barrels daily by 2027, a feat demanding a substantial water supply. This is because oil fields require water or gas injection into wells to maintain equilibrium and enhance well pressure for increased oil production. The Director General of Water in Basra reports a staggering supply of 4,500 to 5,000 liters of water per second to local farms, with some sourcing their water from the rivers.

In Iraq and the Kurdistan Region, there are a total of 15 steel and iron factories, boasting an impressive combined annual production capacity of 4.7 million tons. This substantial production demands a staggering 2.8 billion liters of water. Furthermore, the region is on the brink of welcoming 10 additional iron factories, with an anticipated annual output of 3.18 million tons of iron, necessitating an extra 2.8 billion liters of water. In both Iraq and the Kurdistan Region, there are a combined total of 31 cement companies, comprising both public and private companies and factories. These companies (factories) require a substantial 5.13 billion liters of water, which is equivalent to 50 million cubic meters, to operate at their full production capacity.

In recent times, Erbil has witnessed the operation of a 300 MW steam power plant, made possible by significant advancements in electricity generation. This facility, which now requires 28.15 million liters of water daily, draws its water supply from the Great River. In this context, it is essential to scrutinize the expansion of four critical sectors in Iraq and the consequences of their water consumption. These sectors encompass the production of each barrel of oil, one ton of cement, one ton of glass, and the generation of one megawatt of electricity. This unfolding situation occurs in Iraq, a nation already grappling with drought, desertification, and water scarcity. The vital question that arises is the cumulative impact of these sectors on Iraq's surface and groundwater resources, which are already facing significant stress.

How much water is required to produce a single barrel of oil?

Oil constitutes a substantial 92 percent of Iraq's total exports (2021), the nation's overall exports amounted to $86.298 billion, with oil accounting for a significant $79.788 billion, according to OPEC data. This heavy reliance on oil for national finances, combined with plans to increase oil production by 2027, introduces a heightened risk and pressure regarding water shortages in Iraq. This risk arises from the fact that oil fields require maintaining well balance, and the more oil is extracted, the more water or gas is necessary to uphold this pressure balance. The specific method employed for this purpose varies across Iraq, with central and southern regions relying more on water, while the Kurdistan Region tends to use more gas, further intensifying the challenge.

Based on a 2018 study by Qamar Energy, Iraq has a history of utilizing water for oil production, a method that aligns with the geological characteristics of oil fields and wells. On a general scale, an average of 1.3 to 1.5 barrel of water is typically needed to produce a single barrel of oil, primarily to uphold well equilibrium. If the goal is to boost oil production, this volume of water required is likely to increase accordingly. As per the Director of Water Resources in Basra, the Iraqi Ministry of Water Resources has allocated 7,000 liters of Shatt al-Arab water per second for oil companies. However, not all of this allocation is used by oil companies operating in the extensive oil fields of southern Iraq. In practice, they use between 4,500 and 500 liters per second.

In the context of oil fields in southern Iraq, several water allocations can be noted. For instance, Majnoon oil field uses 160 liters per second, while Nahr Bin Omar similarly uses 160 liters per second. West Qurna-1 is allocated approximately 250 liters per second, and West Qurna-2 uses 200 liters per second, drawing from the Euphrates River. Fayhaa uses 122 liters per second, and Siba uses 100 liters per second, with both fields obtaining their water supply from the Shatt al-Arab. Additionally, the Shatt al-Arab gas-fired power plant uses a substantial 1,000 liters per second for cooling.

The strategy for expanding oil production in Iraq is no longer solely hinged on the arrival of foreign companies, investments, or Iraq's quota within OPEC and OPEC+ for oil exports. The foremost challenge lies in ensuring the availability of water to substitute for the oil that's extracted or to elevate the pressure within the oil fields and wells, as a step in amplifying oil production.

Another noteworthy aspect of this process is tied to the aging oil fields and wells in Iraq, which presently necessitate the augmentation of pressure and the maintenance of pressure equilibrium within these fields and wells. To illustrate, after 60 years of oil extraction in the Rumaila oil field, particularly in its northern section, the internal pressure of the wells has diminished, necessitating the injection of water to boost well pressure. For instance, in 2013, the field's daily production was below 200,000 barrels, yet it surged to 1.2 million barrels per day in 2019 and further increased to 1.4 million barrels per day in 2021.

How much water is required to produce 1 ton of steel and cement?

Currently, there are 15 steel and iron factories in Iraq and the Kurdistan Region, with 12 of them in the Kurdistan Region. These factories collectively possess an annual production capacity of 4.6 million tons of steel and iron, distributed among various provinces as follows: Erbil with 2.06 million tons, Sulaymaniyah with 1.88 million tons, Basra with 350,000 tons, Karbala with 200,000 tons, Mosul with 50,000 tons, and Duhok with 50,000 tons.

Iraq is also strategically increasing its steel and iron production alongside its initiatives in the oil sector. Anticipated to yield an additional 3.18 million tons annually by the end of 2024, this move is set to drive the total production of steel and iron to exceed 7.78 million tons per year, a comprehensive overview of which can be found in Tables 1 and 2.

As per one of the proprietors of steel and iron factories in the Kurdistan Region, a notable contrast exists in water usage for steel and iron production in the Kurdistan Region compared to the broader Iraq. This divergence can be attributed to the adoption of modern technology in the factories. Nevertheless, the water consumption remains at 600 liters per ton. In contrast, the United States, according to the US Environmental Protection Agency, necessitates a minimum of 2,000 liters of water per ton to produce one ton of steel and iron.

With an average usage of 600 liters of water per ton for steel and iron production, a substantial 2.8 billion liters of water are currently used annually in Iraq and the Kurdistan Region to manufacture the 4.7 million tons of domestically produced iron. Notably, the sector is experiencing rapid growth, and by 2024, it is expected to encompass 25 factories, primarily in central and southern Iraq, which will necessitate 1.9 billion liters of water to produce 3.18 million tons of steel and iron annually.

Table 1: Iron Rod Production Levels in Kurdistan Region and Iraq by Provinces

Source: Steel Company, 10-09-2023, Ali Ibrahim / Retrieved on 12-10-2023

Table 2: Number of Companies Currently in the Implementation Phase for Iron and Iron Rod Production by Provinces in the Kurdistan Region and Iraq

Source: Steel Company, 10-09-2023, Ali Ibrahim / Retrieved on 12-10-2023

Annually, 4 billion tons of cement are utilized globally, resulting in the emission of approximately 3 billion tons of carbon dioxide into the atmosphere. This substantial emission accounts for 8 percent of global carbon dioxide emissions, making cement production the second-largest contributor to global warming after oil. Demand for cement continues to rise each year.

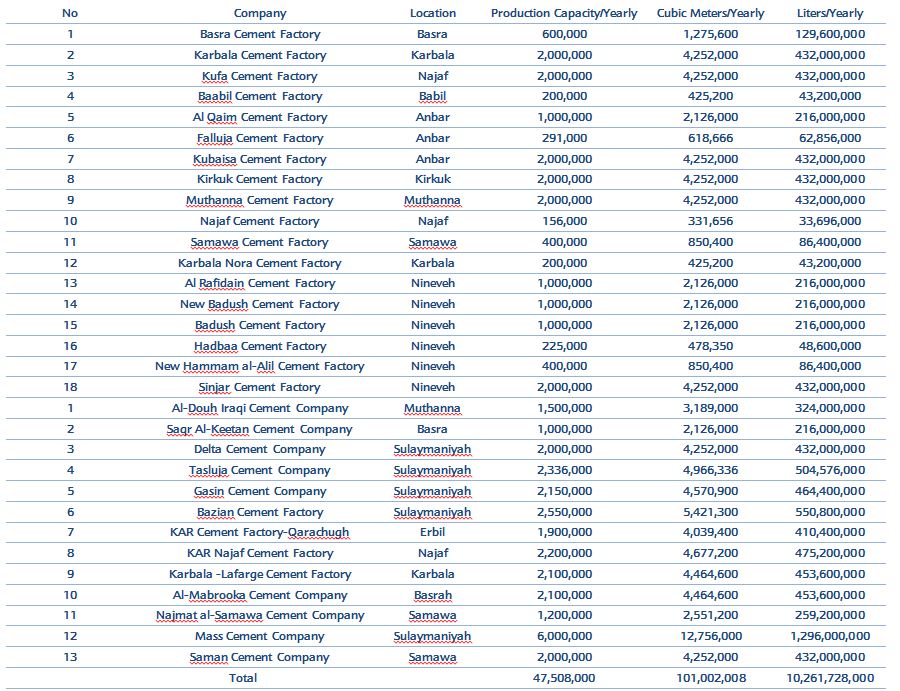

Iraq presently operates 18 state-owned cement companies and 13 private sector cement companies, collectively boasting an annual production capacity of 47 million tons. Within this capacity, public companies contribute 18 million tons, while private sector companies account for a capacity of 29 million tons of cement. If these companies were to operate at full capacity, they would require 101 million cubic meters or 101.26 billion liters of water annually to produce their yearly output. However, when focusing solely on the amount of cement produced annually by private companies, each ton of cement necessitates 2,126 cubic meters or 2,126 liters of water, adding up to a substantial 61 million cubic meters or 61 billion liters of water required.

In the Kurdistan Region, there are seven cement factories, with six of them currently operational and one, Dabin Cement Factory in Erbil, under establishment. These factories have a combined capacity of 16.936 million tons of cement, yet their current production stands at 10.7 million tons, representing 64 percent of their capacity. This production level requires an annual supply of 22 billion liters of water, with the primary water source being rivers and groundwater.

Table 3: Distribution of Public and Private Sector Cement Companies in Iraq and the Kurdistan Region

Source: Cement Global Review, October 12, 2023, and State-owned Cement Companies in Iraq, October 15, 2023

Note: Information is based on data from a cement factory in the Kurdistan Region that produces 15,900 tons of cement daily, indicating a daily water requirement of 5,000,000 cubic meters sourced from the Small River.

* 2.126 cubic meters of water per ton of cement

** 2126 liters of water per ton of cement

How much water is required daily to generate 1 MW of electricity?

There are 11 power plants in total: 3 in Erbil, 5 in Sulaimaniyah, 1 in Garmian, and 2 in Duhok. Khabat steam power plant generates 300 megawatts of electricity daily from the Great River.

Based on the studies, producing one megawatt of electricity per hour requires at least 1,057 gallons, equivalent to over 3,910 liters of water. For a 24-hour steam plant, this translates to 93,861 liters of water per megawatt, which amounts to over 10.27 billion liters of water annually. Remarkably, the Khabat steam power plant sources this substantial water supply directly from the Great River, as confirmed by plant officials. In Iraq, the Shatt al-Arab power plant in Basra cools its electricity generation system using 1,000 liters per second, equivalent to 518 million liters of water over a 24-hour.

Conclusion

The growth of industries in Iraq is substantial. The oil sector alone daily consumes 388 million liters, with certain fields sourcing water from the Euphrates River. The cement sector's annual water consumption, largely from rivers and wells, reaches 10.2 billion liters. Steam electricity production uses 114 million liters, and the steel and iron industries require 2.8 billion liters of water annually.

In light of the growing concern about deteriorating climate conditions in Iraq, the plans to boost oil production and expand other industries raise significant issues. If these expansions proceed without adequate oversight and encourage the use of wastewater and seawater, it will further exacerbate Iraq's environmental challenges by exerting added pressure on surface and groundwater resources.

For over 14 years, starting in 2011, Iraq has been formulating a plan for a collaborative seawater project (CSSP) aimed at providing water from the Gulf to oil fields. Initially slated to be executed by Exxon Mobil, after eight years, Exxon announced the termination of negotiations for the project, leaving the implementation details in a state of uncertainty.

[1] Water pressure, as defined by the WRI, represents the balance between the annual water demand and the renewable water resources. It quantifies how much water is utilized each year relative to the amount of new water that is replenished and can be harnessed. This metric gauges the competition for domestic water resources and aims to narrow the disparity between water supply and demand, categorizing regions as more or less susceptible to water scarcity. In a scenario where a country experiences elevated water pressure, it signifies that a minimum of 80percent of the available water supply is being utilized.